ABS is a thermoplastic such as all FDM materials.

ABS is very well suited for functional parts, since it 80% having the properties of an injection molded part.

Especially the surface finishing by chemical polishing, and the good bending properties make ABS a popular Material.

ABS is used a lot in the industry. So car bumpers are for example made from this material.

For very large or very flat parts, ABS tends however to the so-called "warping" (bend) and to stress cracking.

Advantages

Disadvantages

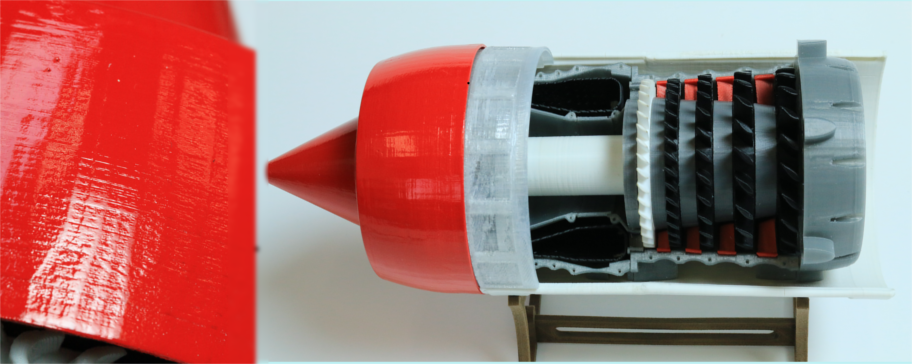

ABS is used mostly to manufacture end usable parts.

Function parts housing up to busts, ABS is a real Alroundtalent.

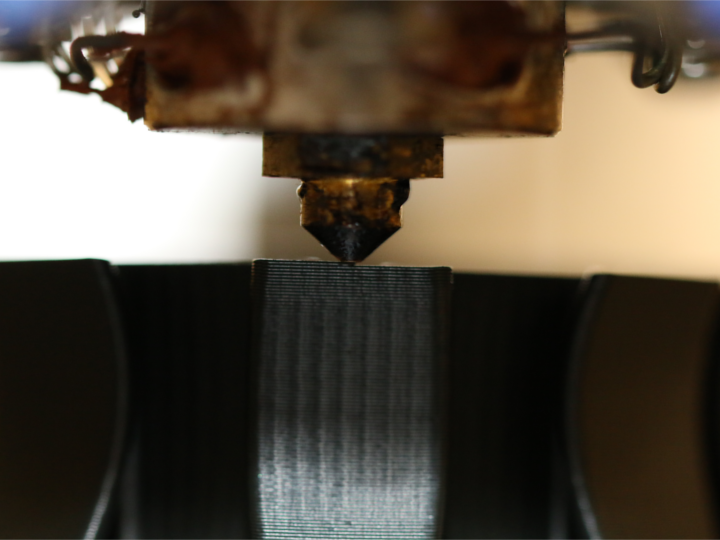

ABS is produced in so-called FDM process.

FDM means literally & quot; Fused Deposition Modeling & quot;.

FDM is one of the simpler methods of 3D printing.Manufactured components exhibit

visible layers on (layers). The advantage of this technology is the pressure in a

high variation of materials and the direct use of technical

Plastics. The material is genuinely applied and thus differs

most other procedures, with materials with approximate properties

work. Another advantage is the possibility of closed cavities.

FDM is not suitable for small parts, because they overheat.

The procedure:

The model is broken down into layers of 0.1-0.2 mm.

Now, a plastic wire is pressed through a heating nozzle and a viscous

State puts. Controlled pressure head is now leaving the contour of the component a CNC

and while applying the desired layer thickness.

Washable support structures from alcohol prevent a hang from overhangs.

Shipping within

8 working days

Minimum wall thickness

1 mm

The smallest Detail

0.3 mm

Maximum dimension

� 170 mm x 285 mm

When ordering before 12 PM, we ship within 2 working days. �

Price

30% surcharge

The surface of your part is determined by the technology and the chosen material. Therefore, we offer several post-processing steps. This affects the cost, but also the quality of your model.

The natural surface of ABS is perfect if you want your model just as functional or demonstration prototype. So you get the material and procedures based on the surface we can make because nothing else as to print your part, to remove the insulators and to send it to you.

Available colors:

Black, white, semi-transparent, green, grey, blue, Orange, red, yellow, pink, Brown, gold

ABS material directly onto glossy can be used as single FDM polishing.

This is achieved by a chemical polishing procedure.

Your part is sanded and then swung through a hot mist of chemicals. The chemical is environmentally friendly and is not bound by the plastic also. < br > The device will arrive so no residue when friends.

The "fog" briefly breaks the surface of the component and brings them to the 'flow', thus it smoothes itself non-contact.

Another big advantage of this Polish is that the stability and abrasion resistance your part greatly improved them!Another big advantage of this Polish is that the stability and abrasion resistance your part greatly improved them!

What is to be observed on polished models::

.Geschliffene have no high-gloss surface models in ABS. You have a slightly rough but very smooth surface.

All parts are sanded by hand and then sandblasted. For this reason, may it be your part

in hindsight will be rejected if it is not to edit by hand.

What is to be observed on polished models::

Of course, you can also paint ABS 3D models.

Here, the quality and RAL color can be chosen. The basic version of the painting is a simple �Spray Paint�.

This means that your component is easily sanded and then painted. Stage of construction, and the similar are still easily recognizable.

The highest quality level is the paint in premium (car paint) quality. For this purpose must be booked "polishing".

Your part is sanded, polished, gef�llert, wet sanded and painted.

ABS parts can also make a wonderful coating.

For this purpose, your model is sanded, and then coated with your desired material. In this case, a coating with Gold or silver is possible.

| Copper | 99,99% Cu | IMDS Nr. 736943 |

| Matt nickel, from Sulfamatelektrolyt | 99,95% Ni | IMDS Nr. 748706 |

| High-gloss nickel | >99,50% Ni | IMDS Nr. 749088 |

| Gold plating 24ct. | 24 Karrat Au | IMDS Nr. 756617 |

| Silver plating | 99,99% Ag | IMDS Nr. 757803 |

| Chrome plating | from the trivalent electrolyte, RoHS Compliant | IMDS Nr. 756617 |

| Black chrome plating | electrically conductive, Black Chrome coating | IMDS Nr. 10629626/1 |

| Electroless Nickel Plating | hochphosphorig, 13% Phosphor als NiP | IMDS Nr. 326271538 |

| Tin plating | 99.98% Sn, RoHS-Konform | |

| Bismut | our Bismudan� electrolyte, 99,95% Bi |

| Unit | Value | ||

|---|---|---|---|

| Tensile strength | MPa | 32-56 | |

| Elongation at break | % | 20 | |

| Hardness | HRC | n/a | |

| Heat resistance | �C | 94 | |

| Impact resistance | kJ/m� | 60 | |

| Density | g/cm� | 1,04 | |

| Water absorption | % | 0,4 | |

| Chemical resistance | Ethanol, Mineral oils | ||

| Weather | Resistant | ||