Tango materials are available in Black and in White.

This material has rubber-like properties and can be set in the Shore hardness.

Also, this parts such as rubber linings and seals can now be produced by 3D printing .

Especially the high elongation is at break of the material and the rubbery feel

For Tango, we're unable to provide a fixed price or formula. Tango parts are calculated only on manual request

Tango parts are used to simulate gums or rubber parts.

Tango is made in the Polyjet process.

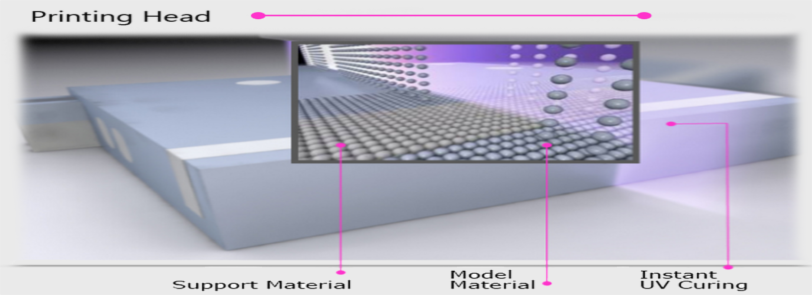

PolyJet means long photopolymer jetting and describes the layers applying UV hardening material by means of nozzles.

The procedure:

Your model on the computer is broken down into layers of 0.035 mm.

They are sent to the printer. A print head with several hundred nozzles side by side only moves in a straight motion over the printing bed. In the places where your part is to be created, activate the corresponding nozzles and spray material onto the printing bed. This hardened immediately by a very strong UV light source. When on the point at which the printer is a overhang, including support material is sprayed.

This process is repeated layer to layer until your part completely is printed.

After printing, the component is placed in a blast cabinet and freed with a 120 bar water jet of support.

Because the material is water soluble,

so parts can be extract also "inside" supports. Nevertheless, the cleaning of the parts is a strain on the material, which is why we require a minimum wall thickness of 0.8 mm.

Shipping within

8 Working days

Tolerance

Better than ± 0,15 mm

Minimum wall thickness

0,8 mm

Smallest Detail

0,032 mm

Maximum dimension

300 x 280 x 150 mm

No priority service is available for Tango parts

Price

---

Parts of tango can not be treated.

Available colors:

White;, Black

| Unit | Value | ||

|---|---|---|---|

| Tolerance | ± | 0,15 | |

| Tensile strength | MPa | n/a | |

| Elongation at break | % | 220 | |

| Hardness | Shore | adjustable | |

| Thermal resistance | °C | 54 | |

| Impact resistance | J/m | n/a | |

| Density | g/cm³ | 1,13 | |

| Water absorption | % | 0 | |

| Chemical resistance | n/a | ||

| Weather | not Resistant | ||