PA12-CS is under the SLS materials by far the most stable.

Among all plastics that we offer, PA12-CS is the most stable and hardest material.

To which it can be made resistant to pressure by thermochemical treatment. Thus, parts are possible by the air-or water-bearing.

A uniquely high surface quality results during Coloring. The surface is completely sealed and smooth, the surface quality of injection molding thus achieved the stability and durability of a SLS part..

To which it has with 170 ° C in addition the highest heat resistance of all plastics in our offer.

PA12-CS is very extremely solid without being brittle..

PA12-CS is produced by PA powder mixing with ceramics.

Components in PA12-CS are not calculated in cm³. is would be not fair to this material.

SInstead a mixed calculation of the basic dimensions (length, width, height), the required orientation, capacity(cm³)of construction, etc. calculated.

The formula for this is beyond the scope here.

PA12-CS is always used when a component is needed, which is designed to withstand extreme loads, must have a high quality finish and pressure-resistant (airtight), must be waterproof, abrasion-resistant and temperature resistant.

This material is probably our best all-around.

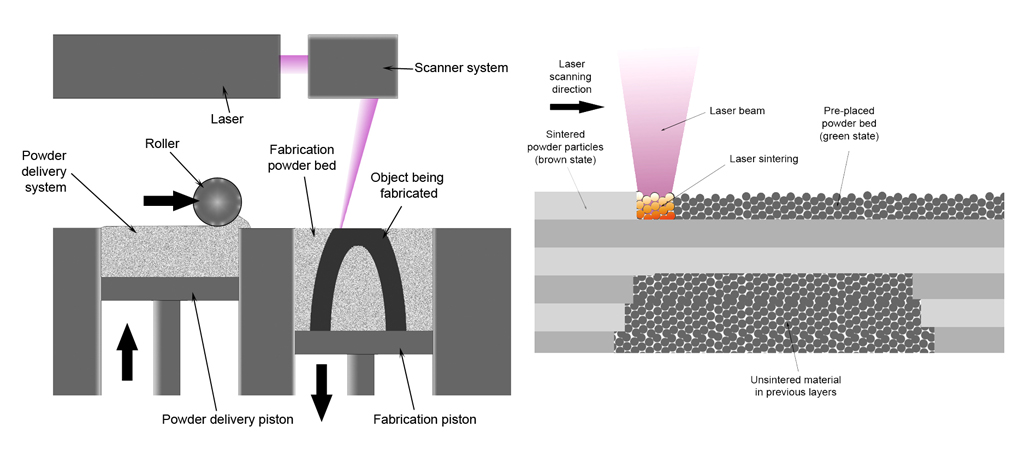

PA12-CS is produced in the SLS method. This powder-based procedure has helped to bring out the 3D printing as where it is presently.

This method cost extremely, robust components can produce injection molded parts in no way inferior.

SLS means Selectives laser sintering and referred to the partial melting of powder materials by using a laser.

The exposure parameters can be manipulated to produce different properties.

The procedure:

Your model is disassembled at the computer in layers of 0.12 mm and sent to the machine.

Now a tank with your desired equipment is

filled. A 0, 12mm-thick layer over the entire width is applied to a pressure bed.

The inner part of the machine is heated to about 100 ° C. A laser lit the powder

and increases the temperature at this point for a fraction of a second above the melting point of the material.

At this point the material is short and liquid connects.

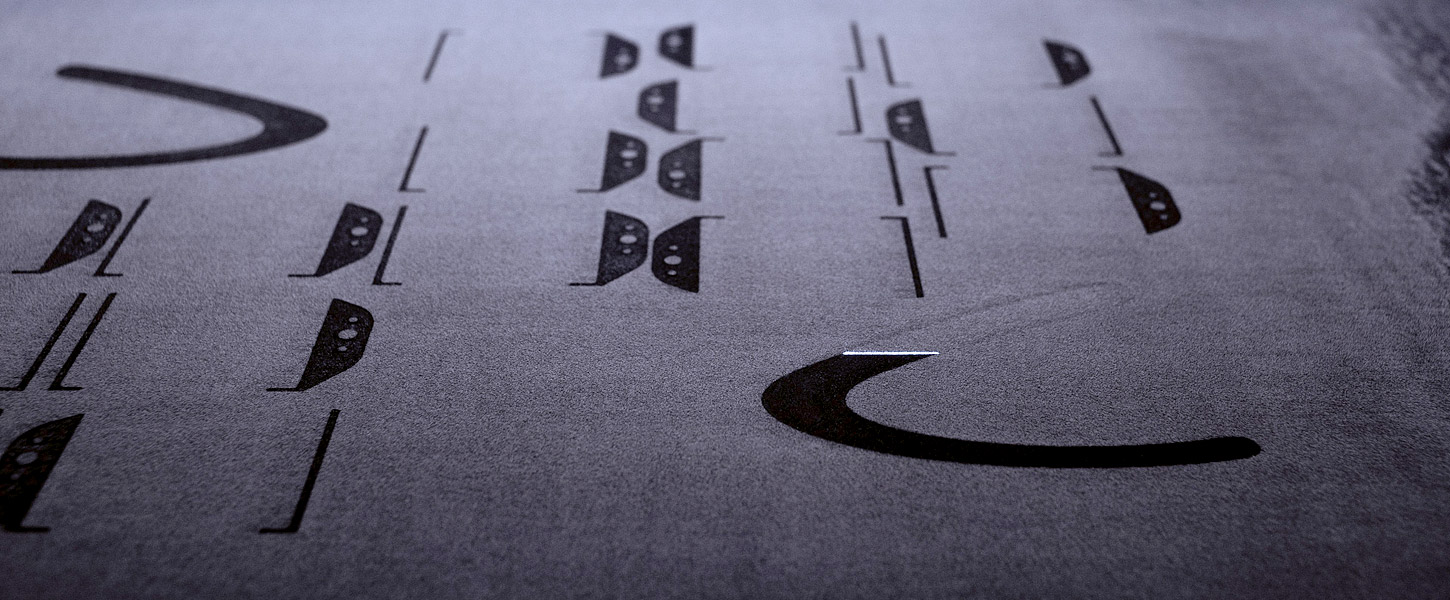

All surfaces that belong to your part are produced in this layer. Now the build platform is lowered and a new layer. This is repeated until your component is ready.

The unmelted powder surrounds your component and is at this time also as a support structure. This allows the printing of 'floating' components (approximately 2 rings that do not touch during printing, but connected).

Your component is now freed from the powder and any residues are blown.

As an additional step, your component is at Fabb-it even sandblasted to make sure all powder residues are away and to improve the surface again.

Shipping within

8 Working days

Tolerance

Better than ± 0,15 mm

Minimum wall thickness

0,8 mm

Smallest Detail

0,3 mm

Maximum dimension

700 x 380 x 560 mm

For PA12-CS no Priority service is available.

Price

---

The surface of your model is determined by the technology and the chosen material. Therefore, we offer several post-processing steps. This affects the cost but also the quality of your model.

The natural surface of PA12-CS is perfect if you want your model just as functional or demonstration prototype. So you'll get the material and procedures based on the surface view, as we are doing nothing more than print your part, stream and ship it to you.

Available colors:

White;

By coloring: Black, Blue, Red, Yellow, Grey, Orange, Brown

Coloring gives you the possibility to get your component in color on PA-CS.

The coloring process is relatively simple. Your component is placed in a staining solution and heated, thus the color penetrates into your component.

It is approximately a thickness of 0.2 - 0.3mm colored. This means your component is not vulnerable to scratching, core shows but when machining back his Whiteen.

The case color used is resistant to chemicals and heat.

The coloring is offered in the standard colors

Black, Grey, Purple, Blue, Green, Orange, Red und Yellow. Special colours on demand.

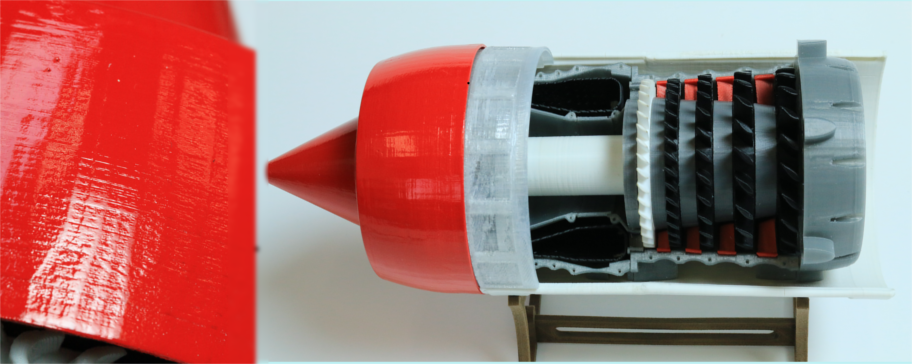

Soft-touch is a special type of painting. The surface feels very soft after painting and smoothed on.

SLS parts with soft-touch are by far the closest to injection-molded parts with regard to interface, look and feel.

The parts are sanded by hand, primed and painted leading to a perfect surface without visible construction stages.

You won't believe the product was printed here.

Of course, you can also paint the models PA CS 3D.

Here, the quality and RAL color can be selected. The basic version of the painting is a simple "spray paint".

This means that your component is easily sanded and then painted. Construction stages and the similar are still easily recognizable.

The highest quality is the quality in premium (car paint). This "Polishing" must be booked with. This "Polishing" must be booked with.

Your part is sanded, polished, filled, wet sanded and painted.

PA-CS Parts can be wonderfully coated also.

To do this, your model is sanded and then coated with your requested material. Here also a coating with as gold or silver is possible.

| Copper | 99,99% Cu | IMDS Nr. 736943 |

| Matt nickel, from Sulfamatelektrolyt | 99,95% Ni | IMDS Nr. 748706 |

| High-gloss nickel | >99,50% Ni | IMDS Nr. 749088 |

| Gold plating 24ct. | 24 Karrat Au | IMDS Nr. 756617 |

| Silver plating | 99,99% Ag | IMDS Nr. 757803 |

| Chrome plating | from the trivalent electrolyte, RoHS Compliant | IMDS Nr. 756617 |

| Black chrome plating | electrically conductive, Black Chrome coating | IMDS Nr. 10629626/1 |

| Electroless Nickel Plating | hochphosphorig, 13% Phosphor as NiP | IMDS Nr. 326271538 |

| Tin plating | 99.98% Sn, RoHS-Konform | |

| Bismut | our Bismudan® electrolyte, 99,95% Bi |

| Unit | Value | ||

|---|---|---|---|

| Tolerance | ± | 0,15 | |

| Tensile strength | MPa | 60 | |

| Elongation at break | % | 10 | |

| Hardness | Shore | n/a | |

| Thermal resistance | °C | 170 | |

| Impact resistance | kJ/m² | n/a | |

| Density | g/cm³ | 1,5 | |

| Water absorption | % | 0 | |

| Chemical resistance | Very resistant | ||

| Weather | Resistant | ||