TPU is a flexible, rubbery and permanently usable material. The flexibility is similar to a pencil eraser (Shore A 92).

Made from a fine Whitely powder are parts that are highly flexible, durable and resistant.

TPU is extremely abrasion resistant. Unfortunately, the detail is not as high as in other SLS materials.

The material is a thermoplastic polyurethane.

Components made of TPU 92-A are calculated per cm³ and a one-time handling fee

TPU 92-A parts are suitable for skin contact. Parts are manufactured from TPU blows to absorb or must have a hard-rubber-like flexibility and yet to remain permanently usable.

This material is often used for gadgets, flexible models or functional parts such as. stop padding

TPU 92A is manufactured in SLS proces. This powder-based procedure has helped to bring out the 3D printing as where it is presently.

This method cost extremely, robust components can produce injection molded parts in no way inferior.

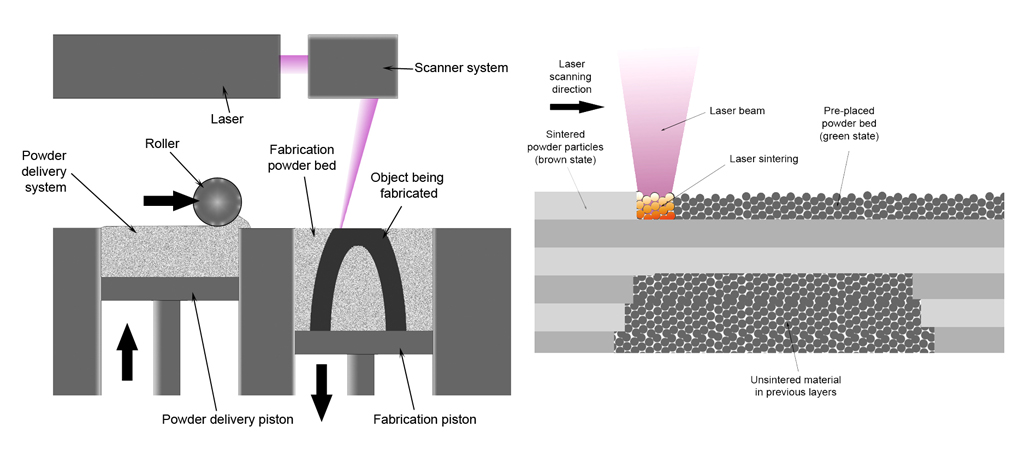

SLS means Selectives laser sintering and referred to the partial melting of powder materials by using a laser.

The exposure parameters can be manipulated to produce different properties.

The procedure:

Your model is broken down at the computer in layers of 0.12 mm and sent to the machine.

Now a tan is filled with your desired equipmen. A 0, 12mm-thick layer over the entire width is applied to a pressure bed.

The inner part of the machine is heated to about 100 ° C. A laser lit the powder.

At this point the material is short and liquid connects.

All surfaces that belong to your part are produced in this layer. Now the build platform is lowered and a new layer. This is repeated until your component is ready.

The unmelted powder surrounds your component and is at this time also as a support structure. This allows the printing of 'floating' components (approximately 2 rings that do not touch during printing, but connected).

Your component is now freed from the powder and any residues are blown.

As an additional step, your component is at Fabb-it even sandblasted to make sure all powder residues are away and to improve the surface again.

Shipping within

10-15 Working days

Minimum wall thickness

1 mm

Smallest Detail

0,5 mm

Maximum dimension

320 x 270 x 300 mm

No priority service is available for TPU 92-A

Price

---

The surface of your model is determined by the technology and the chosen material. Therefore, we offer several post-processing steps. This affects the cost but also the quality of your model.

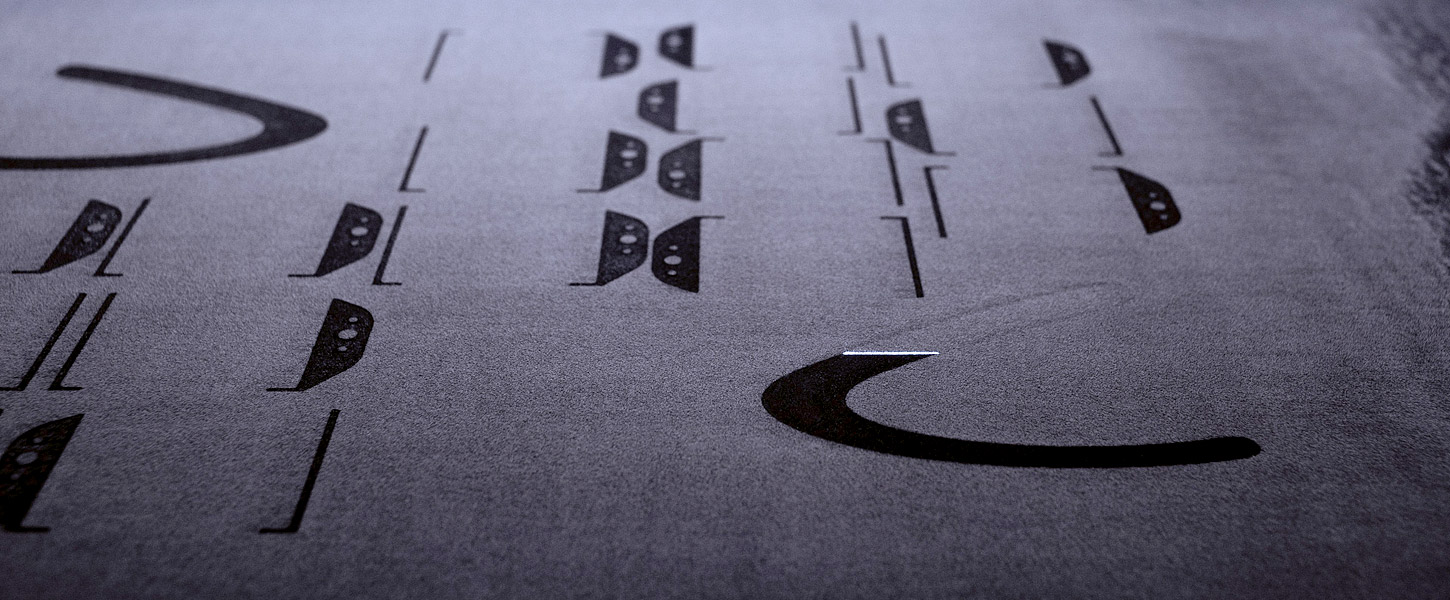

The natural surface of TPU-92a is perfect if you want your model just as functional or demonstration prototype. So you'll get the material and procedures based on the surface view, as we are doing nothing more than print your part, stream and ship it to you.

Available colors:

Whitely

By coloring: Black

Coloring is available only in the black color in TPU

| Unit | Value | ||

|---|---|---|---|

| Tensile strength | MPa | 27 | |

| Elongation at break | % | 400 | |

| Hardness | Shore | A 92 | |

| Thermal resistance | °C | 90 | |

| Impact resistance | kJ/m² | n/a | |

| Density | g/cm³ | 1,2 | |

| Water absorption | % | n/a | |

| Chemical resistance | Very resistant | ||

| Weather | Resistant | ||