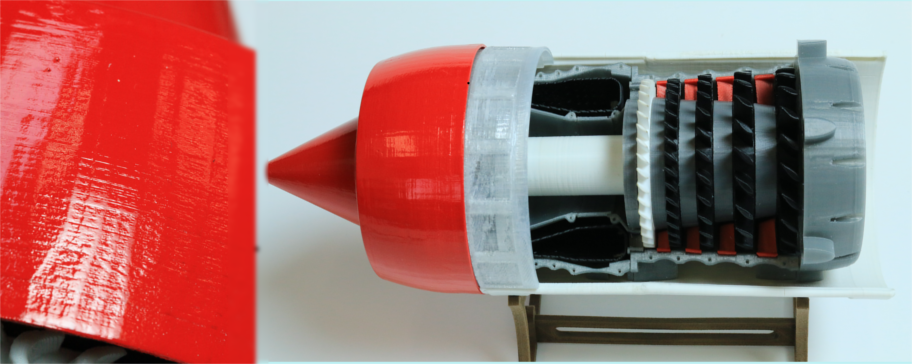

Titanium is produced in the DLM process. This means that the component is pure, free of voids or inclusions and is solid at 99.8%.

The properties of this material allow are comparable with those of an alluminum components.

Titanium in the DLM process has not the classic glossy look of a machined component made of titanium. Instead, it is more greyish and matte with a slightly rough surface.

Some Airbus and rocket NASA are already flying with serially produced 3D printing parts made of aluminum.

Titanium can be automatically calculated.

The price is calculated by the cm³ of your part

Titanium can be used in many different ways. Mostly it is used in medical technology. But it is very well for the manufacture of jewellery.

Like all DLM materials can also be titanium on glossy polishing.

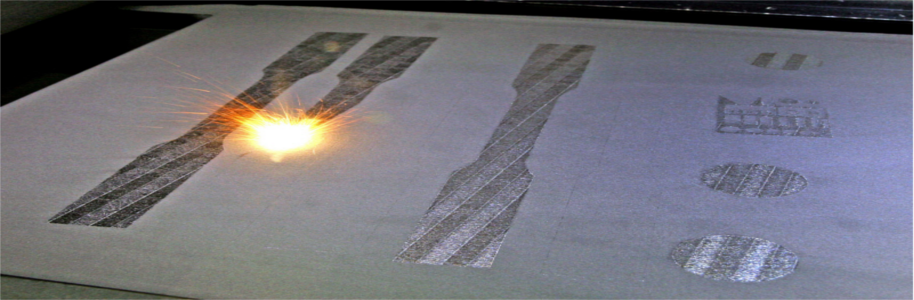

Titanium is produced in the DLM process.DLM means direct laser melting and referred to it directly by melting metal powder to a component.

There will be no further processing steps unless the separation of the pressure required Platform.

The material is subjected to resolve tensions after printing a heat treatment.

The procedure:

Your model is broken down into layers on the computer and sent to the machine.

Now, a printing bed with exactly this thickness is filled with metal powder. A very strong laser now merges the powder at the locations where your part is to be built.

This occurs under a protected atmosphere of argon or nitrogen.

This process is repeated until your component manufactured.

The remaining powder is sucked out and your part manuelly cut from the base plate.

When "Finish" your part is in a heat treatment furnace to anneal it.

Shipping within

22 Working days

Possible with manual request within 7 days

Tolerance

± 0,05 mm

Minimum wall thickness

0,4 mm

Smallest Detail

0,25 mm

Maximum dimension

250 x 250 x 400 mm

There is unfortunately no available priority service for titanium.

Price

---

The surface of your model is determined by the technology and the chosen material. Therefore, we offer several post-processing steps. This affects the cost but also the quality of your model.

Of course you can also paint 3D models from Titan.

Here, the quality and RAL color can be selected. The basic version of the painting is a simple "spray paint"..

This means that is your part lightly sanded and then painted. Construction stages and the similar are still easily recognizable..

The highest quality is the quality in premium (car paint). This "Polishing" must be booked with. This "Polishing" must be booked with.

Your part is sanded, polished, filled, wet sanded and painted.

Titanium parts can be coated also wonderfully.

To do this, your model is sanded and then coated with your requested material. Here also a coating with as gold or silver is possible.

| Copper | 99,99% Cu | IMDS Nr. 736943 |

| Matt nickel, from Sulfamatelektrolyt | 99,95% Ni | IMDS Nr. 748706 |

| High-gloss nickel | >99,50% Ni | IMDS Nr. 749088 |

| Gold plating 24ct. | 24 Karrat Au | IMDS Nr. 756617 |

| Silver plating | 99,99% Ag | IMDS Nr. 757803 |

| Chrome plating | from the trivalent electrolyte, RoHS Compliant | IMDS Nr. 756617 |

| Black chrome plating | electrically conductive, Black Chrome coating | IMDS Nr. 10629626/1 |

| Electroless Nickel Plating | hochphosphorig, 13% Phosphor as NiP | IMDS Nr. 326271538 |

| Tin plating | 99.98% Sn, RoHS-Konform | |

| Bismut | our Bismudan® electrolyte, 99,95% Bi |

| Unit | Value | ||

|---|---|---|---|

| Tolerance | ± | 0,25 mm | |