Durus is a Polyjet material which has been specially prepared to be flexible and easy example. Clicking applications withstand.

Durus we printed as a liquid resin and hardened by UV. The material is very resistant to shock.

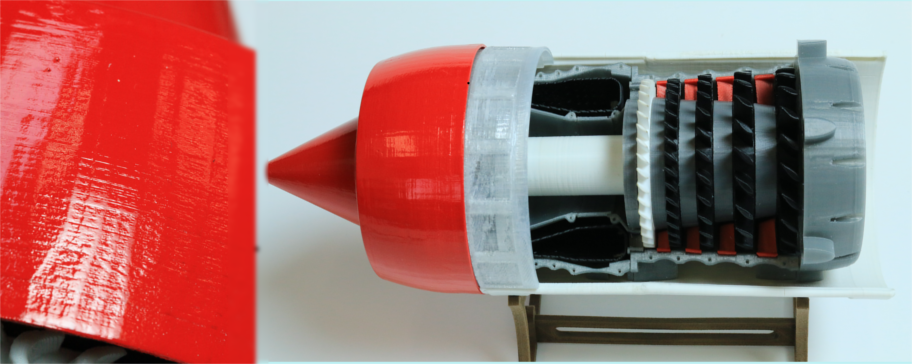

The processing of extreme details can represent and create sharp edges.

Vero materials are calculated on the basis of volume and component size. This is due to the manual work that is necessary to each component.

The formula is:

[(Length x width x height) / 2] x 0,15 + (Volume in cm³ x 1,71)

Bsp.:

A part with the masses 10x2x2 cm and a Volumen of 30 cm³

(10x2x2)= 40

40 / 2=

20

20x0,15=

3

3+(30x1,71)=

54,30 €

Durus is used if detailed models or injection molding prototypes to be made that can be tested (function test).

Durus is far superior in strength and Vero flexibility

Durus is manufactured in the Polyjet process.

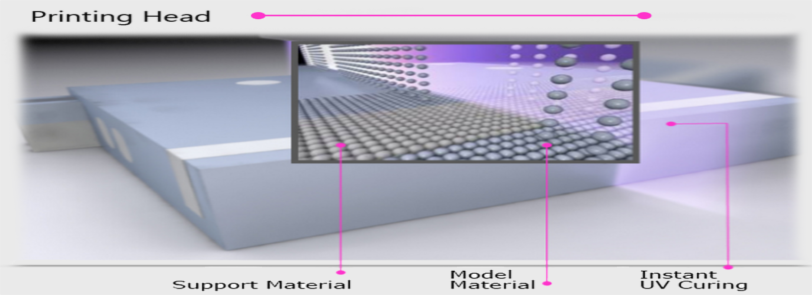

PolyJet means advertised Photopolymer Jetting, and the layer-by-layer describes the Application of UV-curing Material by means of nozzles.

The procedure:

Your model is disassembled at the Computer in layers of 0.035 mm.

They are sent to the printer.

They are sent to the printer. A print head with several hundred jets now side by side runs in a straight motion of the printing bed.In the places where your part is to be created, activate the corresponding nozzles and spray material onto the printing bed. This hardened immediately by a very strong UV light source. If there is an overhang over at the site which the printer, support material is injected below.

This process is repeated Layer for Layer is printed until your part is complete.

After printing, the component is placed in a blast Cabinet with a 120 bar water-jet of the Support freed.

Because the material is water soluble, parts can thus also "inside" extract supports. Nevertheless, the cleaning of the parts is stressful for the Material, which is why we need to have a minimum wall thickness of 0.8 mm.

Shipping costs

8 Working days

Tolerance

± 0,15 mm

Minimum wall thickness

0,8 mm

smallest Detail

0,032 mm

Maximum dimension

300 x 200 x 150 mm

When ordering before 12am we ship within 24 hours. »

Price

30 % surcharge

The surface of your model is determined by the technology and the chosen material. Therefore, we offer several post-processing steps. This affects the cost but also the quality of your model.

Available colors:

White

Polishing

"Polishing" poly Jet parts costs no impact. The printer is set to a high gloss.

But Please visit our Design guidlines for poly Jet, to see what high-gloss surfaces are possible.

Of course, you can also paint models from durus 3D.

Here, the quality and RAL color can be chosen. The basic version of the painting is a simple "Spray Paint"

This means that your part is lightly sanded and then painted. Construction stages and the similar are still easily recognizable.

The highest quality is the quality in premium (enamel). This "polishing" must be booked with.

Your part is sanded, polished, filled, wet sanded and painted.

| Unit | White | ||

|---|---|---|---|

| Tolerance | ± | 0,15 | |

| Tensile strength | MPa | 20-30 | |

| Elongation at break | % | 50 | |

| Hardness | Shore | 78 | |

| Thermal resistance | °C | 34 | |

| Impact resistance | J/m | 30 notched | |

| Density | g/cm³ | 1,13 | |

| Water absorption | % | 0 | |

| Chemical resistance | n/a | ||

| Weather | not resistant | ||