VeroWhitePlus, VeroBlackPlus, VeroGreyPlus and VeroBluePlus we summarized result of constant properties, the term Vero family.

It differs only the color, so that we can summarize them here.

Vero is, based on UV curing resin, plastic. High gloss can be achieved by applying liquid surface and a very good dimensional stability.

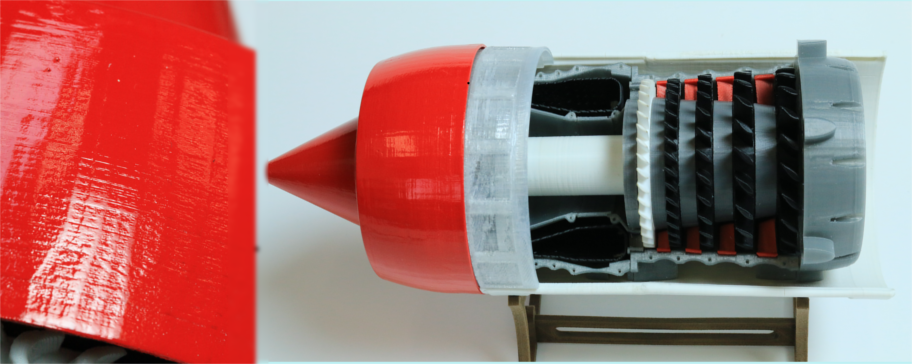

Vero has the highest detail all procedures and can provide even the smallest details.

The only restriction in the complexity of the parts is the fact that we have to rinse with a jet of water to remove the support material.

However, while models such as "ball in a ball" are possible.

The minimum wall thickness can be much lower than in some cases. Here then must very cautious.

If you need a part under 0.8 mm wall thickness, us please send a manual request. (up 0.2 mm possible)

Vero materials calculated on the basis of volume and component size. This Calculation is through manual work which is necessary in every part.

The formula is:

[(Length x width x height) / 2] x 0,15 + (Volumen in cm³ x 1,37)

Bsp.:

A part with dimensions 10 x 2 x 2 cm and a volume of 30 cm³

(10x2x2)= 40

40 / 2=

20

20x0,15=

3

3+(30x1,37)=

44,10 €

Vero parts are usually then taken to hand when a visual prototype of a molded part is to be built. The material is very close to the injection-moulded parts in feel and look.

Vero is also excellent to create molds for example silicone through its high surface quality.

We were able to produce some used parts. As long Vero is not under UV exposure, it is aging even faster than conventional plastics.

Vero is made in Polyjet procedure.

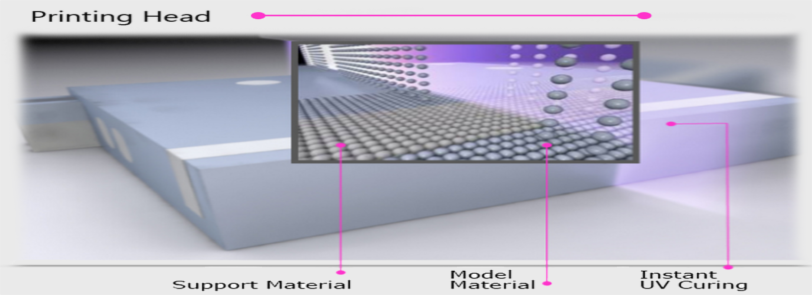

PolyJet means long photopolymer jetting and describes the layers applying UV hardening material by means of nozzles.

The procedure:

Your model on the computer is broken down into layers of 0.035 mm.

They are sent to the printer. A print head with several hundred nozzles side by side only moves in a straight motion over the printing bed. In the places where your part is to be created, activate the corresponding nozzles and spray material onto the printing bed. This hardened immediately by a very strong UV light source. When on the point at which the printer is a overhang, including support material is sprayed.

This process is repeated layer to layer until your part completely is printed.

After printing, the component is placed in a blast cabinet and freed with a 120 bar water jet of support.

Because the material is water soluble,

so parts can be extract also "inside"supports. Nevertheless, the cleaning of the parts is a strain on the material, which is why we require a minimum wall thickness of 0.8 mm.

Shipping within

8 Working days

Tolerance

Better than ± 0,15 mm

Minimum wall thickness

0,8 mm (bis 0,2 mm in Einzelfällen)

Smallest Detail

0,032 mm

Maximum dimension

300 x 200 x 150 mm

When odering before 12 at noon, we ship within 24 hours. »

Price

30 % extra charge

The surface of your model is determined by the technology and the chosen material. Therefore, we offer several post-processing steps. This affects the cost but also the quality of your model.

Available colors:

White;, Blue, Grey, Black

Polishing

"Polishing" will cost no extra charge at Polyjet parts. The printer is set only on glossy.

But please visits our Design guidlines to Polyjet to see which areas are possible in high gloss.

Of course you can also paint 3D models from Vero.

Here, the quality and RAL color can be selected. The basic version of the painting is a simple "spray paint".

This means that is your part lightly sanded and then painted. Construction stages and the similar are still easily recognizable..

The highest quality is the quality in premium (car paint). This "Polishing" must be booked with. This "Polishing" must be booked with.

Your part is sanded, polished, filled, wet sanded and painted.

| Unit | Value | ||

|---|---|---|---|

| Tolerance | ± | 0,15 | |

| Tensile strength | MPa | 50-65 | |

| Elongation at break | % | 10-25 | |

| Hardness | Shore | 74-78 D | |

| Thermal resistance | °C | 54 | |

| Impact resistance | J/m | 20-30 | |

| Density | g/cm³ | 1,18 | |

| Water absorption | % | 0 | |

| Chemical resistance | n/a | ||

| Weather | not Resistant | ||