Resin is actually a through concept for UV-curing liquid plastics.

If you choose Resin provide us the decision of what kind of Material, we take exactly for your pressure.

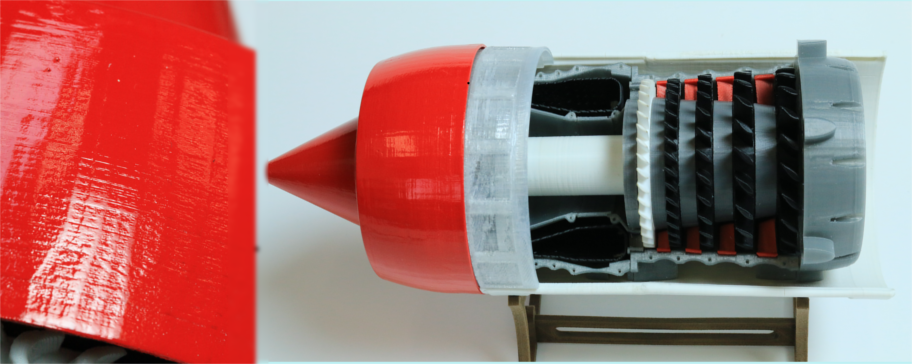

3D prints in SLA have an extremely high surface quality and a very high dimensional accuracy.

It can be presented tiniest details in extremely high resolution.

Most Resin is used in the production of highly detailed projects or the dimensional accuracy for example. Functional and installation tests must be very high.

Advantages

Disadvantages

Sla Resin is always used when a high demand is placed on the surface finish and / or details of the component.

This can indeed be reached with Polyjet but SLA has the advantage that can be printed on all sides and the inner glossy hann.

The only downside is that the portions need to be supported and therefore visible traces formed on part in the post.

Dimensional accuracy is very high in resin parts, because of working with layer thickness of 0.05 mm..

Resin-parts are manufactured in the SLA process.

SLA means Steriolithographie and is the oldest and most mature 3D printing process.

Since working with UV sensitive liquid plastics and no thermals is used to SLA, not warp parts.

The procedure:

Your model is decomposed by a program into individual layers of 0.05 mm.

Now a plate lowered into a bath of resin.

On this record, a UV laser now starts to "draw the contours and shapes of the parts". In all places where the laser exposed the Resinbad, the material hardens.

Now the build platform lowers to a layer thickness down and a slide provides new material on its surface.

This process is repeated layer by layer to your component until it is ready.

During the construction process, your part rests on the insulators .

These are removed after the manuel merge operation and sanded.

Shipping within

8 Working day

Minimum wall thickness

0,8 mm

Smallest Detail

0.05 mm

Maximum dimension

170 x 170 x 210 mm

When ordering before 12 at noon we ship within 2 working days »

Price

30 % extra charge

The surface of your model is determined by the technology and the chosen material. Therefore, we offer several post-processing steps. This affects the cost but also the quality of your model.

Available colors:

Red, Blue, Grey, White;, Black

Soft-touch painting

Soft-touch is a special type of painting. The surface feels very soft after painting and smoothed on.

SLA parts with soft-touch are by far the closest to injection-molded parts with regard to interface, look and feel.

The parts are sanded by hand, primed and painted leading to a perfect surface without visible construction stages.

You won't believe the product was printed here.

After post-curing under a UV lamp and additional Cleaning, we can Polish SLA parts.

What is to be observed on polished models:

Of course you can also paint resin 3D models .

Here it is a grind, the parts not necessary, which makes the process more cost-effective and results in a high-gloss finish.

Resin-Parts can be wonderfully coated also.

In contrast to normal materials, these must not be covered with a conductive layer, as SLA parts are directly coated.

To do this, your model is sanded and then coated with your requested material. Here also a coating with as gold or silver is possible.

| Copper | 99,99% Cu | IMDS Nr. 736943 |

| Matt nickel, from Sulfamatelektrolyt | 99,95% Ni | IMDS Nr. 748706 |

| High-gloss nickel | >99,50% Ni | IMDS Nr. 749088 |

| Gold plating 24ct. | 24 Karrat Au | IMDS Nr. 756617 |

| Silver plating | 99,99% Ag | IMDS Nr. 757803 |

| Chrome plating | from the trivalent electrolyte, RoHS Compliant | IMDS Nr. 756617 |

| Black chrome plating | electrically conductive, Black Chrome coating | IMDS Nr. 10629626/1 |

| Electroless Nickel Plating | hochphosphorig, 13% Phosphor as NiP | IMDS Nr. 326271538 |

| Tin plating | 99.98% Sn, RoHS-Konform | |

| Bismut | our Bismudan® electrolyte, 99,95% Bi |

| Unit | Value | ||

|---|---|---|---|

| Tensile strength | MPa | n/a | |

| Elongation at break | % | n/a | |

| Hardness | HR | n/a | |

| Thermal resistance | °C | n/a | |

| Impact resistance | kJ/m² | n/a | |

| Density | g/cm³ | n/a | |

| Water absorption | % | n/a | |

| Chemical resistance | n/a | ||

| Weather | n/a | ||