Al6Si2O13, Aluminosilcate. Good temperature resistance, low thermal conductivity and high electrical resistance.

Industrial Ceramics can be calculated only manuel

The initial mineral Kaolinite produces mullite as an essential component in the production of porcelain and tiles as well as fireclay bricks.

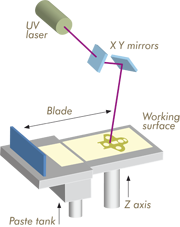

Mullite is produced in the procedure of FCP. FCP means almost ceramic production and is a variation of the SLA process with subsequent refining through burning.

The procedure:

Your model is broken down into layers of 0.2 mm on the computer.

They are sent to the printer. The printer put a 0.2 mm thick layer of a ceramic resin mixture. This mixture hardens now in places where your part is to be created, by a UV laser.

This process is repeated until the component is created..

Now your part is burned, it escapes the resin and compressed the component.

In the end result there is a dense ceramic material which is even medically useful.

Shipping within

on demand

Tolerance

n/a

Minimum wall thickness

0,2

Smallest Detail

0,05

Maximum dimension

coming soon

We offer unfortunately no Priority service for ceramic

Price

---

Post-production services will be updated soon. High gloss polishing and staining on demand..

Available colors:

White, more coming soon

| Unit | Value | ||

|---|---|---|---|

| Flexural strength | g/cm³ | 3,14 | |

| Compressive strength | MPa | n/a | |

| Fracture toughness | MPan1/2 | n/a | |

| Thermal resistance | °C | 2680°C | |

| Impact resistance | kJ/m² | n/a | |

| E-Modul | GPa | n/a | |

| Water absorption | % | 0 | |

| Chemical resistance | Löslich in HNO³ | ||

| Weather | Resistant | ||