A composite 3D printing consists of a gypsum material which after printing with an infiltrate (epoxy resin) is filled.

Through this second step of processing, special design guidelines apply to composite parts.

As a rule of thumb, man can say :

Would your component from wet sand be produced?

Because in front of the Infiltrate, the component is very unstable.

The difference to full Collor parts is the infiltrate.

Through use of epoxy resin, the component is stable and also mechanically editable.

Advantages

Disadvantages

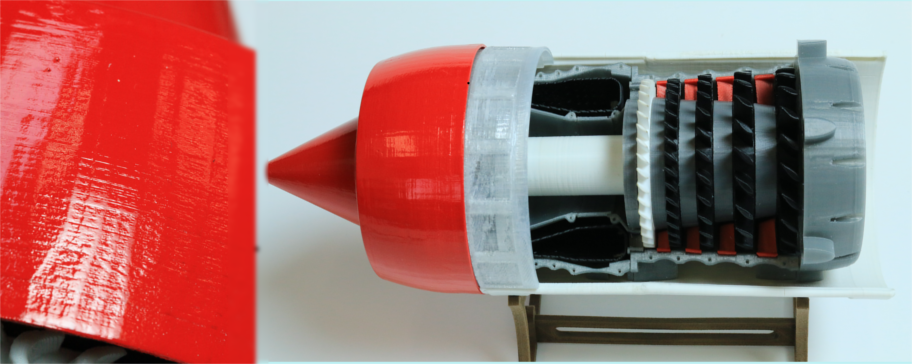

Full-3D prints are very often used for visualizations.

This procedure can provide its customers with a preview of the finished product..

Mostly like, it is used in architecture and interior design.

Composite parts are produced in the so-called Z-print or new Colorjet process.

The procedure:

The model is broken down into layers 0,1-0,2 mm.

Now a layer from gypsum powder equal to coat(layer) is applied on the printing bed.

A print head which is filled with binders, injects it now there where the part is to be created.

This process is repeated until the printer completely printed the component located at the pressure bed and filled with powder.

The loose powder is used as a support structure for overhanging sections.

After printing, the component is carefully removed from the printing bed and cleaned.

At this point in the process, the supply is still very fragile.

After excess powder is removed, the component is covered with epoxy resin.

This penetrates into the supply and then hardens. The result is a stable model at the end.

Shipping within

8 Working day

Minimum wall thickness

2 mm - 3 mm

Smallest Detail

0.3 mm

Maximum dimension

380 x 250 x 200 mm

When ordering before 12 am We will ship within 3 Working days. »

Price

30 % extra charge

The surface of your model is determined by the technology and the chosen material. Therefore, we offer several post-processing steps. This affects the cost but also the quality of your model.

Available colors:

18 million colors, but only one color model Advantages!

Polished models in Fullcollor have no high-gloss surface. They have a slightly rough but very smooth surface.

All parts are sanded by hand and then sandblasted. For this reason, it may be that your part is subsequently rejected if it is not to edit by hand..

What is to be observed on polished models:

Natürlich lassen sich 3D Modelle aus Komposit auch lackieren.

Hierbei wird allerdings nur ein Klarlack verwendet um das Bauteil glatter zu machen.

Of course, you can also paint models from 3D composite.

Here, the quality and RAL color can be selected. The basic version of the painting is a simple "spray paint"..

This means that is your part lightly sanded and then painted. Construction stages and the similar are still easily recognizable..

The highest quality is the quality in premium (car paint). This "Polishing" must be booked with. This "Polishing" must be booked with.

Your part is sanded, polished, filled, wet sanded and painted.

| Unit | Value | ||

|---|---|---|---|

| Tensile strength | MPa | n/a | |

| Elongation at break | % | n/a | |

| Hardness | HR | n/a | |

| Thermal resistance | °C | n/a | |

| Impact resistance | kJ/m² | n/a | |

| Density | g/cm³ | n/a | |

| Water absorption | % | n/a | |

| Chemical resistance | n/a | ||

| Weather | n/a | ||